Call: 08045476123

- New Arrivals

- Featured

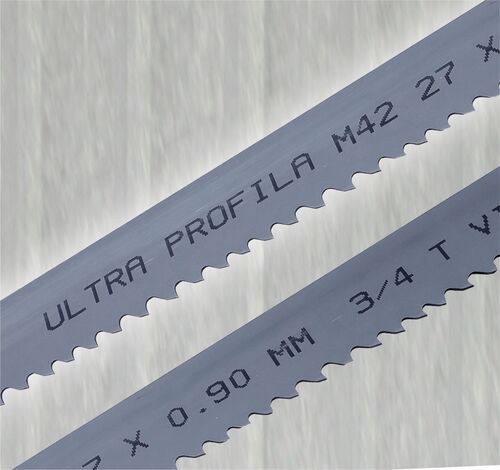

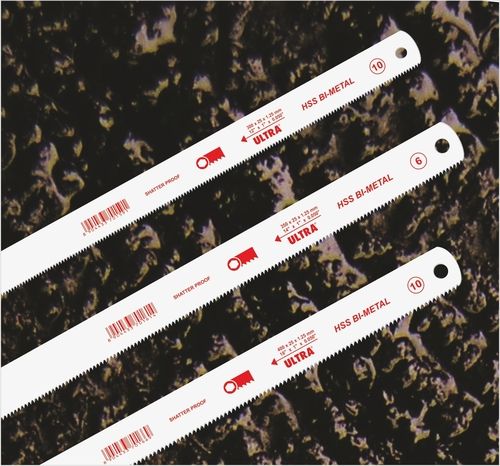

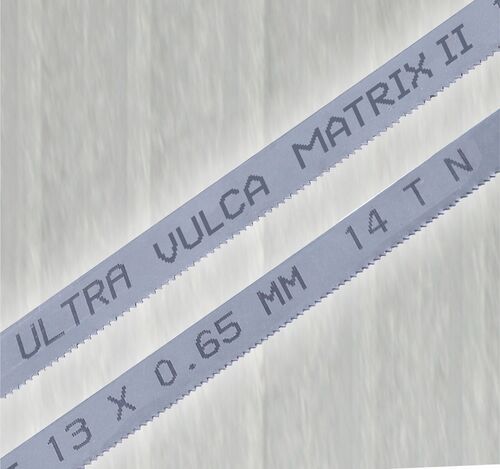

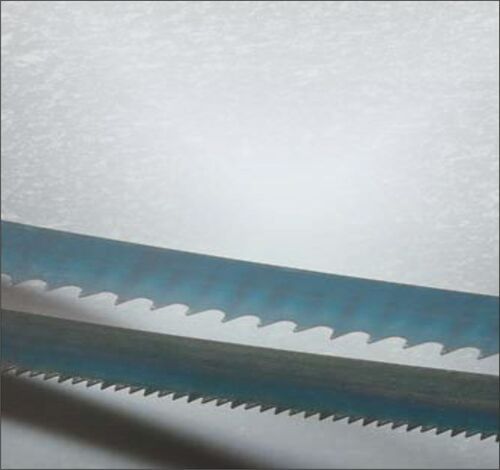

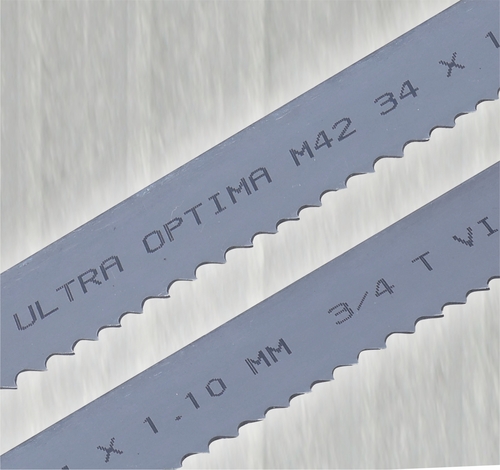

Ultra Tools was set up in 1982 as a manufacturer with the main objective of manufacturing quality Cutting Tools. With business expansion, we stretched our arms for manufacturing Hand Tools and Power Tool Accessories. The company has gained expertise in manufacturing a wide range of tools and accessories such as Hand Hacksaw Blades, Tool Bits, Carbon Steel Bandsaw Blades, Hand Hacksaw Frames and SS Diamond Cutting Wheels. Today our portfolio includes innovative to classic tools and accessories.

Our company is headquartered in Mumbai, India, having production plants at Mumbai and Palghar. Besides, we have an extensive domestic sales network as well as international sales network, where diverse customers needs across the globe is met in a timely and fair manner. We have our great network of exporting products in 45 countries and 100 deals in association for expanding our products reach. Our large variety of products is sold majorly to OEM, DIY and Distributors/ Specialized Retailers. We make direct sales to BHEL, Railways, Steel Units, Defense, etc.

The company is a member of various organizations such as IMTMA, FIEO and Indo German Chambers of Commerce, etc., and proudly boast ISO 9001:2015 certificate.

Exhibition

Our company regularly participates in various domestic and international exhibitions such as IMTEX, etc.

Primary Competitive Advantages

Our company is headquartered in Mumbai, India, having production plants at Mumbai and Palghar. Besides, we have an extensive domestic sales network as well as international sales network, where diverse customers needs across the globe is met in a timely and fair manner. We have our great network of exporting products in 45 countries and 100 deals in association for expanding our products reach. Our large variety of products is sold majorly to OEM, DIY and Distributors/ Specialized Retailers. We make direct sales to BHEL, Railways, Steel Units, Defense, etc.

The company is a member of various organizations such as IMTMA, FIEO and Indo German Chambers of Commerce, etc., and proudly boast ISO 9001:2015 certificate.

Exhibition

Our company regularly participates in various domestic and international exhibitions such as IMTEX, etc.

Primary Competitive Advantages

- Quality based hand and cutting tools

- Hi-tech production and storing facilities

- Cost-effective line of products

- Exporting network in the worldwide

Introduction

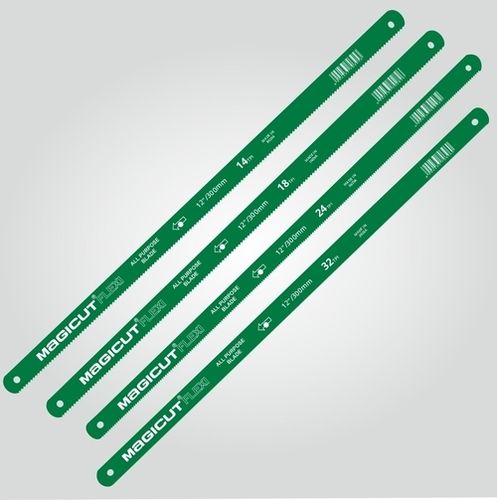

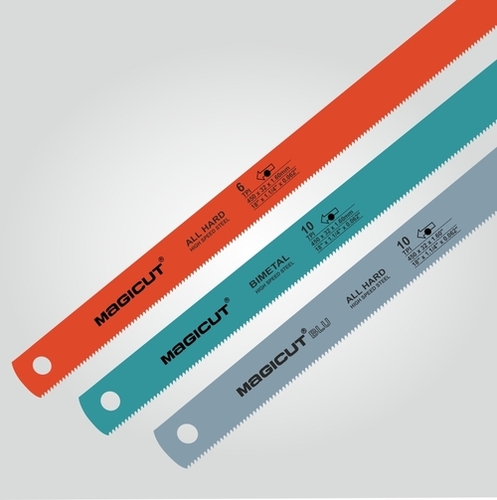

Magicut origins go back to 1951 when the founder, Late Mr. R. C. Gupta opened a hardware retail shop and a few years later started wholesaling as well. In 1963, he started his first factory for engine bearings and gradually expanded to manufacture a variety of products such as Bearing, Diesel Engine Spares, Copper Alloys and Cutting Tools. Over the last many years, through diversification took place, the focus has never shifted away from engineering.

Corporate Philosophy

Our corporate philosophy can be summed up as Customer satisfaction, Reliability, Innovation, quality & Services. We follow a policy of not compromising quality under any circumstance while manufacturing, Band Saw Blades, Circular Saw Blades, Cutting Tools, etc., and a commitment of continuously bringing innovative products and services into the markets. We take our commitments seriously and believe in honoring them.

Environmental Policy

At Ultra Tools, we believe that as a producer, it is our responsibility to contribute our little share in maintaining environment, so we are using required resources efficiently. We are also minimizing waste by following the policy of Recovery, Recycle and Reuse. As a part of our environment saving initiative, we have planted six thousand trees (Approx.) around our Palghar based plant. Also, we are switching our production to more eco-friendly means, using gas furnaces is one of the best examples for the same.

Quality Control

Magicut origins go back to 1951 when the founder, Late Mr. R. C. Gupta opened a hardware retail shop and a few years later started wholesaling as well. In 1963, he started his first factory for engine bearings and gradually expanded to manufacture a variety of products such as Bearing, Diesel Engine Spares, Copper Alloys and Cutting Tools. Over the last many years, through diversification took place, the focus has never shifted away from engineering.

Corporate Philosophy

Our corporate philosophy can be summed up as Customer satisfaction, Reliability, Innovation, quality & Services. We follow a policy of not compromising quality under any circumstance while manufacturing, Band Saw Blades, Circular Saw Blades, Cutting Tools, etc., and a commitment of continuously bringing innovative products and services into the markets. We take our commitments seriously and believe in honoring them.

Environmental Policy

At Ultra Tools, we believe that as a producer, it is our responsibility to contribute our little share in maintaining environment, so we are using required resources efficiently. We are also minimizing waste by following the policy of Recovery, Recycle and Reuse. As a part of our environment saving initiative, we have planted six thousand trees (Approx.) around our Palghar based plant. Also, we are switching our production to more eco-friendly means, using gas furnaces is one of the best examples for the same.

Quality Control

- ISO certificate: Our company boasts of state-of-the-art manufacturing and testing facilities.

- Our success has hinged upon its ability to consistently deliver quality tools conforming to IS, BS, DIN, JIS & ISO standards and its unbending commitment to timely execution of delivery schedules.

- Manufacturing Quality Products

- Continual Improvement in Processes, System & Productivity through Benchmarking & Innovation in our products.

- Involvement of Employees in Continuous Improvements.

- Complying with the requirements of Quality Management System in accordance with the ISO 9001:2000 Standard for manufacturing Band Saw Blades, Sheet Metal Punches, Circular Saw Blades, Cutting Tools, etc.

- Our plant is amongst the modern plants in our country for cutting tools.

- Continuous up-gradation has seen us installing state-of-the-art equipment across our products.

- Hardening Furnaces boast of automatic temperature controls and precise heat sensing radiation pyrometers.

- Once approved the raw materials are sent for further processing where during each stage the quality is carefully monitored by a team of quality inspectors. Just as in the hardening department each batch is carefully tested for micro structure and each tool for hardness. We therefore have full control over the quality of the inputs, and consequently of the end products.

Most Popular Products

- Magicut HHF002 : Aluminum Hacksaw Frame. Heavy Duty Aluminum Handle Epoxy Powder Coated Frame Robust and Compact Less Effort While Cutting Wide Wing Nut for Easy Tensioning Supplied with 127300mm Hand Hacksaw Blade

- Magicut Swift Bimetal M42 8% Cobalt Mini Hole Saws are toothed HSS Strips welded to a tough alloy body and disc. These precision manufactured Mini Hole Saws have outstanding strength, resilience and shatter resistance. Salient Features & Advantages Soild Back Disc for Smooth and Precise Cut Single Piece Construction Precise Tool Geometry More Cutting Depth compare to conventional Holesaws Smooth Cutting Operation Better Rigidity Longer Life

- 100 Star HSS M-2 Tool Bits Made from High Speed Steel bearing tungston-modybdenum for use on relatively soft material. 200 Star HSS M-35 Tool Bits Made from High Speed Steel bearing 5% Cobalt. It is an economical grade for general purpose use in workshop and is best suites for applications involving interrupted cuts and roughing operation. 300 Star HSS M-42 Tool Bits Have a high degree of hot hardness and wear resistance. Made from High Speed Steel bearing 8% Cobalt, these offer top efficiency on difficult-to-machine alloys and high strength steels. 400 Star HSS T-42 Tool Bits Have exceptional wear resistance property. Made of 10% Cobalt bearing High Speed Steel, these have high hot hardness. Edge-holding ability in addition to ample toughness for all types of cutting tool applications including those at high temperatures and speeds. They are especially adopted for roughing or finishing operations where maximum tool life is required; for large- batch automatic lathe work and all types of lathe and boring operations. Available in Square, Round, Flat, Parting Tools and Cut-Off Blades. Call Us for more details. Price will Vary as per specifications required.

- Introducing Magicut Power Hacksaw Blades the precision-engineered solution for accurate cutting, making them the ideal choice for general-purpose work in workshops. These blades are designed with utmost precision, uniformly hardened throughout, featuring a fully hardened back and cutting edge for exceptional durability and performance.

- Magicut Reciprocating Saw Blades are available in Bimetal M42 and Bimetal 8% Cobalt. These are top quality cobalt edge blades boasting of higher productivity and longer life. Blades are available in different thicknesses to meet the flexibility and stiffness requirements for various applications.

- Magicut HHF004 Plastic Handle Hacksaw Frame High Tensile Plastic Handle Epoxy Powder Coated Frame Light Weight for Easy Handling Easy Blade Change Wide Wing Nut for Easy Tensioning Supplied with 12"/300mm Hand Hacksaw Blades

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese